Industrial Nitrogen Maker

Applied Industries:

☆Electronic Industry ☆ Heat Treatment ☆ Coal Mine, Coal Chemical Industry

☆Fine Chemical Industry ☆ Pharmaceutical Engineering ☆ Rubber Industry

☆Food Industry ☆ Aerospace and Weapon Industry ☆ Metallurgical Industry

☆Petroleum, petrochemical and natural gas Industry

Now that the global electronics manufacturing industry is promoting lead-free production, China ‘s electronics industry will follow the same trend. To meet the lead-free standards, more and more manufacturers choose a new type of welding furnace with nitrogen welding protection. To meet the nitrogen requirements of the SMT industry, we developed a solution for special nitrogen gas for SMT with a purity of more than 99.999 %, based on the classical nitrogen generator and considering the characteristics of lead-free welding in the SMT industry, which can ensure the correct activation of the flux, reduce the residual amount of flux, enhance the welding quality, and make the welding surface better.

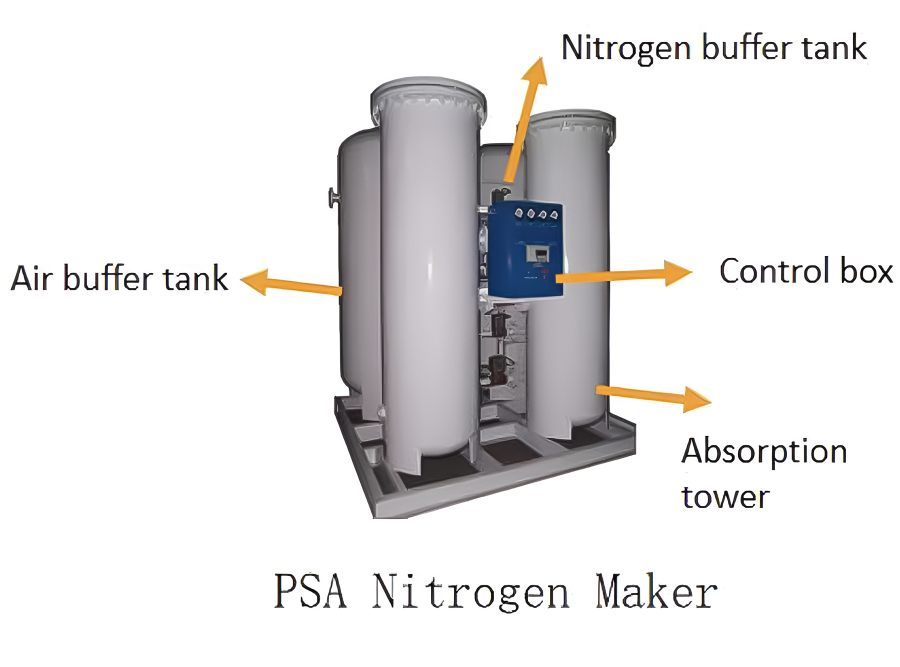

Equipment Features:

High purity nitrogen is produced (purity 99.999%~99.9995%).

High efficiency and low energy consumption; 0.42 KWH power consumed for generation of one cubic meter nitrogen.

the type is standard and thus easier for capacity increase. To increase the nitrogen output, you just need to connect several nitrogen makers in parallel.

Low dew point: -70℃~-40℃, thus welding quality is ensured

It can be contained with a frame to make it clean, tidy and better looking for the high cleanliness requirement in the electronics industry.

Technical Parameters

Nitrogen Output | 1-5000NM³/h(standard state) |

Nitrogen Purity | 95%-99.9995%(non-oxygen content as per the state norms) |

Nitrogen Outlet Dew Point | ≤-70°C(normal pressure) |

Nitrogen Outlet Pressure | 0.1-1.0Mpa (adjustable and stable) |